Clean liquid fuel for heavy industry

Liquium is revolutionising the ammonia production process helping it

align with renewable energy, lower the cost of production and operation & have a broader scale for more applications.

-

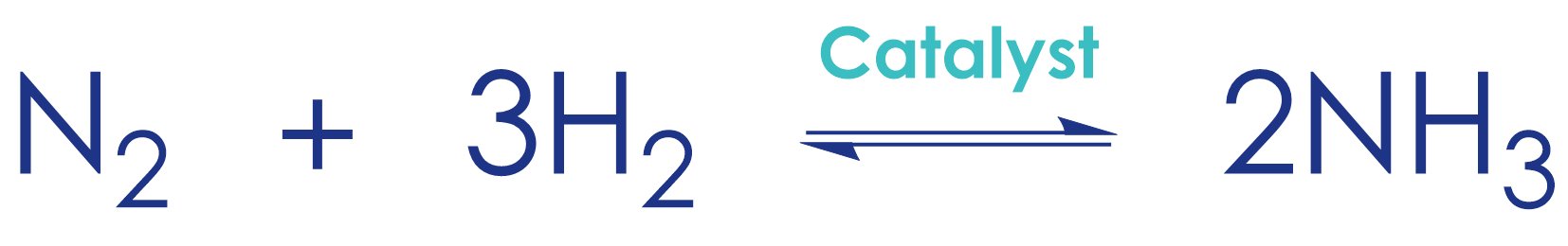

For the past 100 years, ammonia has been made following the Haber-Bosch process, where nitrogen reacts with hydrogen over a catalyst bed at high temperatures and pressures to generate ammonia. Ammonia has then been used in the chemical industry as a nitrogen source building block, and it is also used as a refrigerant. However, its primary use has been in the fertiliser industry, directly or following another reaction made into urea. Ammonia is one of the most significant synthetic chemicals and has a global production of 150-180 million tonnes annually.

-

Ammonia is currently one of the most polluting chemicals on the planet responsible for ~500M tonnes per annum of carbon dioxide. This carbon footprint is primarily due to the consumption of fossil fuels (Coal and natural gas) to produce the energy required to start the reaction and secondly as a source of hydrogen.

Fortunately, making clean (zero carbon) ammonia on an industrial scale is already in development. The fossil fuel energy and hydrogen balance can be solved for using renewable energy solutions and water electrolysis to generate the hydrogen making it a green process. However, green ammonia will likely be more expensive than its brown counterpart.

-

Clean ammonia presents a unique solution to the global decarbonisation effort. Ammonia has the highest energy density per unit volume for any given zero-carbon fuel (i.e. compared to Li-ion batteries, hydrogen, etc). This energy metric is critical for heavy industries such as the maritime sector, where weight is not the primary concern.

Furthermore, clean ammonia distribution will help maintain global energy security in a decarbonised world by allowing clean, renewable electricity to be converted to hydrogen and then to ammonia. The ammonia can then be easily transported worldwide to places where abundant renewable energy is unavailable, or the demand outstrips local supply.

Clean ammonia as an energy carrier is forecasted to be twice the annual supply and has become a central focal point to help the clean energy transition.

Our unique technology is a new catalyst to enable milder working conditions to produce ammonia

AWARDS & RECOGNITION

CSO & Co-Founder, Dr Franck Natali awarded with the Breakthrough Energy Fellowship in its inaugural year (2021) and was the only person to be selected in the southern hemisphere

PATENTED IN 2017, WE HAVE A CLEAR DEVELOPMENT PATH TO SCALE THIS TECHNOLOGY

CEO & Co-Founder, Dr Paul Geraghty presented virtually at the Asian Entrepreneurship Award 2022 and received third prize. Additionally, the team was recognised with The Japan Academic Society for Ventures and Entrepreneurs (JASVE) Award to the most challenging team in solving problems and which is full of entrepreneurship.

INDUSTRY MEMBERSHIP

Liquium has been recognised as one of the most forward-thinking innovators in the Asia-Pacific region by the Cleantech group.

To see the full list and details

Click Here

Let’s talk

We are interested in hearing from keen investors and relevant global industrial companies who are working in these markets.